-

Coolant & Oil Cleaning

Highlights

- Ensures Cost Savings as No Filter Media is required

- Ensures Savings in Coolant Top-Up requirement

- Ensures Savings in Tooling Cost

- Ensures Improvement in Component Quality (no pitting)

- Ensure Removal of Bacteria (no foul smell)

- Ensure Space saving

-

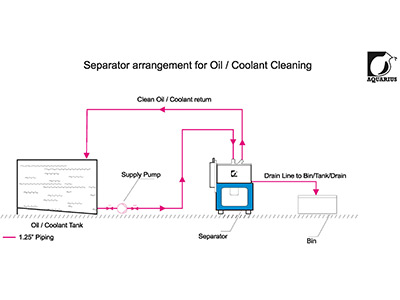

Cutting Oils, Neat Oils, Hydraulic Oils, HFO, Fuel Oils, Coolant Oils, etc. are cleaned very effectively by the separators. The separators’ efficiency can be as high as 98% for all particles above 5 microns.

The separators prove highly beneficial for machining process like Brushing, Honing, Lapping, Deburring, Grinding, Cutting, Drilling, Vibratory Finishing, Cold Forming, Wire drawing, Industrial Washing and many more.

It is very much suited to different materials like Ceramics, Cast Aluminium, Glass, Tungsten Carbide, Molybdenum, Carbon, Brass, etc. in addition to Steel.

The separators can clean Oil up to viscosity of 700 cSt.

Stand-alone as well as centralized systems are available based on customer machine set-ups.

- Paint & Phosphate Sludge Dewatering

- Coolant & Oil Cleaning

- Wire Drawing (High Viscosity Lubricant)

- Glass fines removal

- Water & Waste Water Treatment

- Solvent Recovery and bags

- Solid-Liquid Separations

- Phosphate Sludge Removal

- Degrease Sludge Removal

- Sludge Dewatering & Thickening

- Chemicals & Additives

- Solvent Recycler

- Paint Sludge Skimmer

- Food & Beverages

- Acetone Recovery

- Others