BULLOWS PAINT EQUIPMENT PVT. LTD., PUNE (Paint Sludge Removal)

EQUIPMENT: HYDROFLOTY 4M X 2 Nos. systems with Auto Chemical Dosing System, for their new customers.

SET-UP: The HYDROFLOTY systems are directly connected to specially designed Semi- Downdraft booths, for high-efficiency sludge removal.

For more information about our product range and activities, you are welcome to visit our website

ANEST IWATA MOTHERSON PVT. LTD., GR. NOIDA (Paint Sludge Removal)

EQUIPMENT: HYDROFLOTY 4M X 1 No. system with Auto Chemical Dosing System, for their own paint shop at Greater Noida, UP.

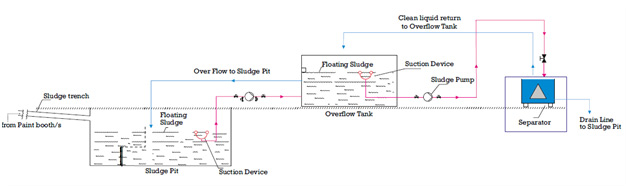

SET-UP: The HYDROFLOTY system is provided with 3 nos. automatic sludge suction devices

to ensure efficient sludge recovery throughout an existing large paint booth. The suction devices have auto-changeover system and hence require no manpower during working (no sludge pit required).

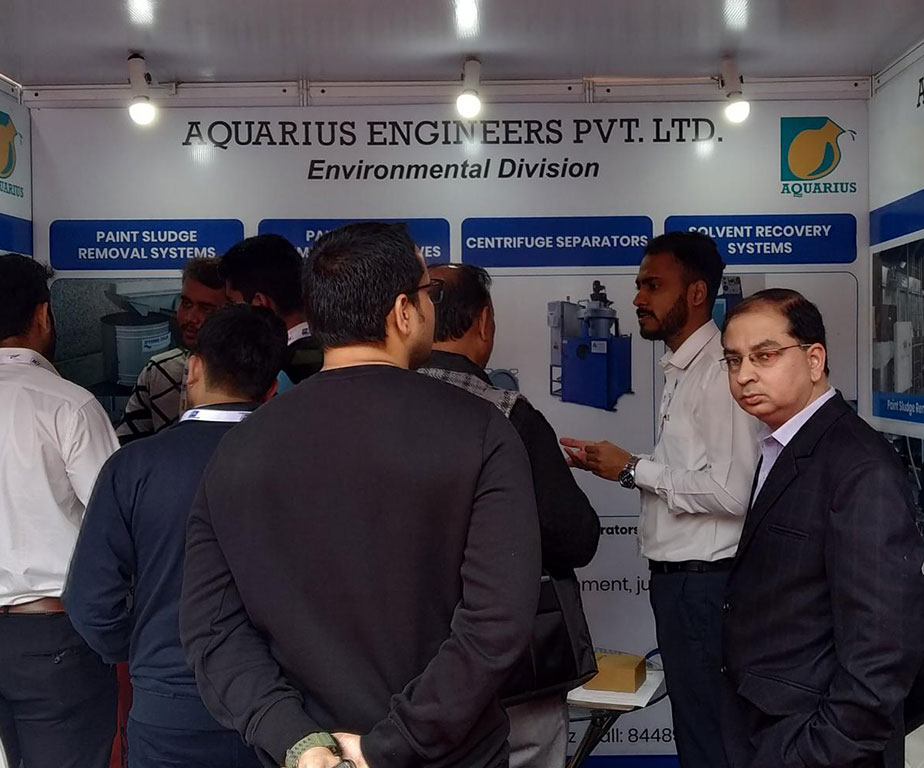

EXHIBITION NEWS

AQUARIUS had participated in the recently conducted IFAT INDIA 2024 ΕΧΡΟ.

The exhibition was a great success, with visitors from diverse fields visiting the AQUARIUS stall to discuss about their various applications and requirements. The HYDROFLOTY 4M model was exhibited at the stall, which proved to be a great crowd puller!

Thanks to all the visitors who made this event a success for us!

For more information about our product range and activities, you are welcome to visit our website

HD FIRE PROTECT, JALGAON (Paint Sludge Removal)

This a repeat order from the customer.

EQUIPMENT: ZLD HYDROFLOTY 4M system along with Auto Chemical Dosing.

SET-UP: Connected directly to a Side Draft Paint Booth (no sludge pit required), at their plant manufacturing firefighting systems.

SANDVIK MINING & ROCK TECHNOLOGY (I) PVT. LTD., PUNE (Paint Sludge Removal)

EQUIPMENT: HYDROFLOTY 4M X 2 Nos. systems with Auto Chemical Dosing for their paint shop at Pune plant.

SET-UP: Each HYDROFLOTY system is connected directly to a Paint Booth (no sludge pit required).

JAMNA AUTO INDUSTRIES, MP (Paint Sludge Removal)

This is the third repeat order for Jamna Auto Industries.

EQUIPMENT: ZLD HYDROFLOTY 6M system along with Auto Chemical Dosing System.

SET-UP: Connected directly to 2 nos. Side Draft Paint Booths having "front water channel" design. Pit-less system.

Surfin Coating Systems Pvt. Ltd., who is supplying the multi-line advance paint shops to the customer, has finalized the order on Aquarius.

For more information about our product range and activities, you are welcome to visit our website

FRITZMEIER MOTHERSON CABIN ENGG LTD (FMCEL), Chennai (Paint Sludge Removal)

EQUIPMENT: ZLD HYDROFLOTY 6M system along with Auto Chemical Dosing System & Sub. Mixer, for their new paint shop coming up at Chennai.

SET-UP: Connected to a very compact sludge pit, which will ensure high efficiency sludge removal and reduced ETP requirement.

Anest Iwata Motherson (AIM), NOIDA, who is supplying the new state-of-art paint shop to FMCEL Chennai, has finalized the order on Aquarius.

SIDDHIVINAYAK AESTHETICS (SAPL), Pune (Paint Sludge Removal)

EQUIPMENT: ZLD HYDROFLOTY 6M system x 2 nos systems along with Auto Chemical Dosing System & Channel Mixer.

SET-UP: Connected directly to 2 nos. Side Draft Paint Booths having "front water channel" design. Pit-less system.

Trutek Systems Combine, Pune, who is supplying the new advanced technology paint shop to SAPL, has finalized the order on Aquarius.

TATA AUTOCOMP SYSTEMS (TACO), Pune (Paint Sludge Removal)

EQUIPMENT: ZLD HYDROFLOTY 9M system along with Auto Chemical Dosing System & Sub. Mixer, for their new paint shop coming up at Chakan, Pune.

SET-UP: Connected to a very compact sludge pit, which will ensure high efficiency sludge removal and reduced ETP requirement.

Trutek Systems Combine, Pune, who is supplying the new state-of-art paint shop to TACO, has finalized the order on Aquarius.

HD FIRE PROTECT, JALGAON (Paint Sludge Removal)

EQUIPMENT: ZLD HYDROFLOTY 4M system.

SET-UP: Connected directly to a Side Draft Paint Booth for automatic paint sludge removal, at their plant manufacturing firefighting systems.

For more information about our product range and activities, you are welcome to visit our website

GAJANAN STEELS, Mumbai (Paint Sludge Removal)

This is theb third repeat order from Gajanan Steels.

EQUIPMENT: ZLD HYDROFLOTY 4M system.

SET-UP: Connected directly to a Side Draft Paint Booth for automatic paint sludge removal, at plant near Baroda for manufacturing plastic products.

PUTZMEISTER INDIA PVT. LTD., GOA (Paint Sludge Removal)

This is the second repeat order from Putzmeister India.

EQUIPMENT: Zero Liquid Discharge (ZLD) HYDROFLOTY 4M system.

SET-UP: Connected to a compact sludge pit, achieving a reduction in their ETP requirement, along with savings in water, space and running cost.

TATA HITACHI CONSTRUCTION, Kharagpur (Paint Sludge Removal)

This is the fourth installation that Aquarius is putting up for Tata Hitachi.

EQUIPMENT: Zero Liquid Discharge (ZLD) HYDROFLOTY 4M system.

SET-UP: Connected directly to 2 nos. Side Draft Paint Booths for automatic paint sludge removal.

NTF INDIA PVT. LTD., Gurgaon (Paint Sludge Removal)

EQUIPMENT: HYDROFLOTY 9M system along with Auto Chemical Dosing System and Redelivery Station, for their new paint shop being installed at Gurgaon plant.

SET-UP: One no. HYDROFLOTY 9M system is connected directly to 3 nos. Paint Booths, using a Redelivery Station. The sludge will be removed from each booth, one-after-the-other, using an auto-changeover system.

Mexmon Technologies, Gurgaon, who is supplying the new advanced paint shop to NTF India, has finalized the order on Aquarius.

For more information about our product range and activities, you are welcome to visit our website

CIE AUTOMOTIVE INDIA LTD. (Formerly Mahindra CIE Automotive Ltd.), Pune (Paint Sludge Removal)

EQUIPMENT: HYDROFLOTY 4M system along with Auto Chemical Dosing System and Redelivery Station, for their existing paint shop at Urse, Pune.

SET-UP: Connected to existing paint booth, without sludge pit, using a Redelivery Station.

FRITZMEIER MOTHERSON CABIN ENGG LTD (FMCEL), Pune (Paint Sludge Removal)

EQUIPMENT: HYDROFLOTY 6M system along with Auto Chemical Dosing System, for their new paint shop coming up at Chakan, Pune.

SET-UP: Connected to a well-designed, low-volume sludge pit, which will ensure high efficiency sludge removal and reduced ETP requirement.

Trutek Systems Combine, Pune, who is supplying the new state-of-art paint shop to FMCEL Pune, has finalized the order on Aquarius.

TOYODA GOSEI SOUTH INDIA PVT. LTD., BIDADI, (Paint Sludge Removal)

EQUIPMENT: HYDROFLOTY 4M X 4 NOS. systems with Redelivery Stations and Auto Chemical Dosing Systems, for their new paint shop coming up at Bidadi, Karnataka.

SET-UP: Each HYDROFLOTY system is connected directly to a specialized Auto Paint Booth system (no sludge pit required).

Parker Engineering India, Gurgaon, who is supplying the new robotic high-tech paint shop to Toyoda Gosei South India, has finalized the order on Aquarius.

MARUTI SUZUKI INDIA LTD., MANESAR (Grating Sludge Removal)

The order is for 2 nos. "Automatic Grating Sludge Collection & Separation Systems" being installed at Maruti Suzuki's plants at Manesar & Kharkhoda. It is a First-of-a-Kind system being installed in India by AQUARIUS.

AQUARIUS is supplying a 2-stage grating paint sludge collection & separation system. The grating sludge is removed by an auto high-pressure blasting system installed by Maruti Suzuki. The sludge coming off the gratings, along with the fines, is effectively collected, chemically treated and removed by the AQUARIUS system. The clean water is returned for reuse in the system.

The equipment comprises of a special filtration system for the removal of heavy paint sludge, followed by a HYDROFILTER system for the removal of the sludge fines. Special in-line Chemical Dosing systems are also provided for treatment of the removed sludge.

Taikisha Engineering India Pvt. Ltd. , Gurgaon, who is supplying the complete state-of-art system to Maruti Suzuki, has finalized this equipment order on AQUARIUS.

BURGEON ENGINEERING PVT. LTD., GURGAON (Paint Sludge Removal)

EQUIPMENT: ZLD HYDROFLOTY 6M system with Auto Chemical Dosing System for their customer paint shop in Gujarat.

SET-UP: HYDROFLOTY 6M system is connected to a compact recirculation tank, which is connected directly to 3 nos. Paint Booths.

FLEETGUARD FILTERS PVT. LTD., NANDUR (Paint Sludge Removal)

This a Repeat Order from the customer.

EQUIPMENT: ZLD HYDROFLOTY 4M system along with Redelivery and Auto Chemical Dosing System.

SET-UP: Connected directly to a Side Draft Paint Booth (no sludge pit required), at their plant in Nandur.

NTF INDIA PVT. LTD., GURGAON (Paint Sludge Removal)

This is a Repeat Order .

EQUIPMENT: ZLD HYDROFLOTY 4M x 3nos. systems along with Auto Chemical Dosing Systems, for their new paint shop being installed at Manesar. No sludge pit is required.

SET-UP: HYDROFLOTY 4Mx3 nos. system connected to 3 nos. Paint Booths.

Mexmon Technologies, Gurgaon, who is supplying the new advanced paint shop to NTF India, has finalized the order on Aquarius.

GAJANAN STEELS, Mumbai (Paint Sludge Removal)

This is the fourth repeat order from Gajanan Steels.

EQUIPMENT: ZLD HYDROFLOTY 4M system with Auto Chemical Dosing System.

SET-UP: HYDROFLOTY 4M connected directly to 2nos. Side Draft Paint Booths, using a front water channel design. No sludge pit is required.

EXHIBITION NEWS

AQUARIUS had participated in the recently conducted CII SURFACE COATING SHOW 2024, in Delhi. The exhibition was a great success, enabling a good interaction with existing as well as new clientele. The HYDROFLOTY 4M model was exhibited at the stall, which helped the clients to understand the HYDROFLOTY system with all of its benefits. Thanks to all the visitors who made this event a great success for us!

NTF INDIA PVT. LTD., Gurgaon (Paint Sludge Removal)

EQUIPMENT: HYDROFLOTY 9M system along with Auto Chemical Dosing System and Redelivery Station, for their new paint shop being installed at Gurgaon plant.

SET-UP: One no. HYDROFLOTY 9M system is connected directly to 3 nos. Paint Booths, using a Redelivery Station. The sludge will be removed from each booth, one-after-the-other, using an auto-changeover system.

Mexmon Technologies, Gurgaon, who is supplying the new advanced paint shop to NTF India, has finalized the order on Aquarius.

For more information about our product range and activities, you are welcome to visit our website http://www.aquariusconsult.biz.

FRITZMEIER MOTHERSON CABIN ENGG LTD (FMCEL), Pune (Paint Sludge Removal)

EQUIPMENT: HYDROFLOTY 6M system along with Auto Chemical Dosing System, for their new paint shop coming up at Chakan, Pune.

SET-UP: Connected to a well-designed, low-volume sludge pit, which will ensure high efficiency sludge removal and reduced ETP requirement.

Trutek Systems Combine, Pune, who is supplying the new state-of-art paint shop to FMCEL Pune, has finalized the order on Aquarius.

TOYODA GOSEI SOUTH INDIA PVT. LTD., BIDADI, (Paint Sludge Removal)

EQUIPMENT: HYDROFLOTY 4M X 4 NOS.systems with Redelivery Stations and Auto Chemical Dosing Systems, for their new paint shop coming up at Bidadi, Karnataka.

SET-UP: Each HYDROFLOTY system is connected directly to a specialized Auto Paint Booth system (no sludge pit required).

Parker Engineering India, Gurgaon, who is supplying the new robotic high-tech paint shop to Toyoda Gosei South India, has finalized the order on Aquarius.

TATA MOTORS, LUCKNOW (Paint Sludge Removal)

AQUARIUS is installing an Automatic Paint Sludge Removal System, HYDROFLOTY 9M, connected to sludge pit, for their new state-of-art paint shop coming up at Lucknow, along with an Auto Chemical Dosing System and a special Submersible Mixer/Propeller for the thorough mixing of chemicals and efficient paint sludge removal.

Electrocoat Equipments, Pune, who is supplying the new state-of-art paint shop to TATA Motors, has finalized the order on Aquarius.

VARROC POLYMERS, RANJANGAON, PUNE (Paint Sludge Removal)

AQUARIUS is installing a Dual HYDROFLOTY System comprising of 2 nos. Automatic Paint Sludge Removal Systems, HYDROFLOTY 9M, for a single sludge pit provided in the paint shop coming up at Ranjangaon.

AQUARIUS is also providing an Auto Chemical Dosing System and a special Submersible Mixer/Propeller for the thorough mixing of chemicals and efficient paint sludge removal.

Electrocoat Equipments, Pune, who is installing the hi-tech paint shop at Varroc, has finalized the order on Aquarius.

STEEL STRIPS WHEELS LTD., MEHSANA (Paint Sludge Removal)

AQUARIUS is installing an Automatic Paint Sludge Removal System, HYDROFLOTY 9M, connected to their existing sludge pit, in their plant at Mehsana Gujarat, which is installed in strategic alliance with their Korean partner.

AQUARIUS is also providing an Auto Chemical Dosing System and a special Submersible Mixer/Propeller for the thorough mixing of chemicals and efficient paint sludge removal from the sludge pit.

SARATHA ELECTROPLATERS, CHENNAI (Paint Sludge Removal)

Saratha Electroplaters are specialized in Zinc & Zinc Nickel Electroplating and serve industries such as Hyundai Motors, Maruti Udyog, Visteon, etc.

AQUARIUS is installing an Automatic Paint Sludge Removal Systems, HYDROFLOTY 4M along with Automatic Chemical Dosing System & Chemicals, for their new paint shop coming up at Chennai. AQUARIUS will fit the HYDROFLOTY as a compact unit with the paint booth. This ensures high efficiency paint sludge removal and also avoid the need of civil sludge pit.

Shri Vishnu Engineering, Coimbatore, who is supplying the new compact paint shop to the customer, has finalized the order on Aquarius.

JAMNA AUTO INDUSTRIES, MALANPUR, MP (Paint Sludge Removal)

This is a repeat order for Jamna Auto Industries, who is the leading manufacturer of high quality suspension systems in India.

AQUARIUS is installing an Automatic Paint Sludge Removal Systems, HYDROFLOTY 6M along with Automatic Chemical Dosing System & Chemicals, for their new paint shop coming up at Malanpur. AQUARIUS has suggested the “front water channel booth design”, which will assist in high efficiency paint sludge removal and avoid the need of civil sludge pit.

Surfin Coating Systems Pvt. Ltd., who is supplying the new state-of-art paint shop to the customer, has finalized the order on Aquarius.

WIPRO INFRASTRUCTURE ENGINEERING, JAIPUR (Paint Sludge Removal)

Wipro Infrastructure Engineering is setting up a new manufacturing facility to make hydraulic cylinders and allied products in Jaipur.

AQUARIUS is installing an Automatic Paint Sludge Removal Systems, HYDROFLOTY 9M along with Automatic Chemical Dosing System & Chemicals, for their new paint shop coming up at Jaipur. AQUARIUS will also be providing a special submersible mixer/propeller for the efficient mixing of chemicals and sludge collection from the sludge pit.

Leo Surface Coatings Pvt. Ltd., Pune, who is supplying the new advanced technology paint shop to the customer, has finalized the order on Aquarius.

CONDUCTOR CORE TECHNOLOGIES, PUNE (Solvent Recovery)

CCT make advanced conductors for overhead transmission powerlines.

AQUARIUS is installing a Solvent Recovery System, model ALPHA 30, which has a capacity of cleaning 30 litres of dirty solvent per batch. The Recycler is built in strict compliance with CE & ATEX directives and undergoes extensive safety testing.

DANA INDIA, PUNE (Solvent Recovery)

DANA Group is a well-established, high technology auto-parts manufacturer in India.

AQUARIUS is installing a Solvent Recovery System, model ALPHA 15, which has a capacity of cleaning 15 litres of dirty solvent per batch.

XCMG, CHENNAI (Solvent Recovery)

XCMG is the 3rd largest construction machinery company in the world. Their product range includes excavators, loaders, road machinery, etc.

AQUARIUS is installing a Solvent Recovery System, model ALPHA 15, which has a capacity of cleaning 15 litres of dirty solvent per batch.

CRESCENT FOUNDRY PVT. LTD., KOLKATA (Paint Sludge Removal)

Crescent Foundry is one of the largest manufacturers, suppliers and exporters of Manhole Cover, Ductile Iron and Counterweight from India. Crescent Foundry caters to varied sectors which include Agriculture, Telecom, Railways, Municipal and many more.

AQUARIUS is installing an Automatic Paint Sludge Removal Systems, HYDROFLOTY 4M along with Automatic Chemical Dosing Systems & Chemicals, for their paint shop coming up at Kolkata. AQUARIUS has suggested the “front water channel booth design”, which will assist in high efficiency paint sludge removal, which will avoid the need of civil sludge pit.

Bullows Paint Equipment Pvt. Ltd., who is supplying the new paint shop to Crescent Foundry, has finalized the order on Aquarius.

ALP AEROFLEX INDIA PVT. LTD., ALWAR (Paint Sludge Removal)

ALP is a USD 200 million Group and globally acknowledged as the pioneer in Polymer based products in India. ALP Aeroflex is a joint venture of ALP Overseas of India and The Eastern Polymer Industries of Thailand for manufacturing of EPDM and Nitrile Rubber insulation sheets for thermal & acoustic insulation.

AQUARIUS is installing 4 nos. of Automatic Paint Sludge Removal Systems, HYDROFLOTY 4M along with Automatic Chemical Dosing Systems & Chemicals, for their new state-of-art automatic paint shop coming up at Alwar. AQUARIUS has suggested the “front water channel booth design”, which will assist in high efficiency paint sludge removal, which will avoid the need of civil sludge pit.

Amba Tech Engineering, who is supplying the new paint shop with Anest Iwata, has finalized the order on Aquarius.

PUTZMEISTER INDIA PVT. LTD., KUNDAIM, GOA (Paint Sludge Removal)

PIPL manufactures state-of-art Concrete Pumps, Concrete Boom Pumps, Mobile Line Pumps and Stationary Boom Placers.

AQUARIUS is installing an Automatic Paint Sludge Removal System, HYDROFLOTY 4M along with Automatic Chemical Dosing System, for their existing paint shop. AQUARIUS is also providing the required Paint Booth Chemicals.

With the changes suggested by Aquarius in their existing sludge pit, the sludge removal efficiency has increased substantially at PIPL.

WABTEC INDIA, KOLKATA (Automatic Paint Sludge Removal)

Wabtec is a global provider of equipment, systems, digital solutions and value-added services for the freight and transit rail industries.

AQUARIUS is installing an Automatic Paint Sludge Removal System, HYDROFLOTY 4M

along with Auto Chemical Dosing System, for the Bullows paint booth. The front water channel design

of booth ensures high sludge removal efficiency and no need for sludge pit. Bullows Paint Equipment Pvt. Ltd.,

who is supplying the new paint shop to Wabtec, has finalized the order on Aquarius.

SANJAY INDUSTRIES (VIJAY), KHURAI, MP (Automatic Paint Sludge Removal)

Sanjay Industries is a leading agricultural machinery manufacturer with the brand name of "VIJAY". They manufacture a wide range of threshers and other agricultural equipment, in Khurai, Sagar, MP.

AQUARIUS is installing an Automatic Paint Sludge Removal System, HYDROFLOTY 9M, to suit the customer's high production, along with Auto Chemical Dosing System. The Hydrofloty will be connected to the sludge pit in their upcoming paint shop.

MAHINDRA & MAHINDRA, MUMBAI (Paint Sludge Removal)

The Automotive unit of Mahindra at Kandivali has placed a prestigious order on Aquarius for an Automatic Paint Sludge Removal System, HYDROFLOTY model 9M and Auto Chemical Dosing System, for their existing sludge pit. A special feature is provided that will remove sludge from 2 sections of the pit automatically. They will also be using Aquarius Chemicals for efficient sludge separation. A special submersible mixer has also been provided to achieve efficient mixing of the chemicals.

HEALTHIUM MEDTECH, KUNIGAL (Solvent Recovery System)

Healthium Medtech manufacture a large range of medical equipment. Aquarius is supplying an advanced Solvent Recycler, ALPHA 200 suitable for Zone 2 operations.

This recycler has a capacity of 200 liters and comes with an Auto Loading System. The Recycler is built in strict compliance with CE & ATEX directives and undergoes extensive safety testing.

SHREE GAJANAN STEEL PRODUCTS, MUMBAI (Paint Sludge Removal)

Gajanan Steels is a leading name in the supply of total UV Coating lines. The customer has placed a repeat order on Aquarius. The fist installation consisted of 2 nos. Side Draft Paint Booths connected together with a common front water channel design, as suggested by Aquarius, which is working excellently well using our Special Chemicals. The new order will have 3 nos. Side Draft Booths with a common front water channel. Aquarius is installing the Zero Liquid Discharge Automatic Paint Sludge Removal System, HYDROFLOTY model 4M & Auto Dosing System for their new U V Coating line.

CII SURFACE & COATING EXPO 2023 CHENNAI

The exhibition was a great success. Clients were very impressed with the Hydrofloty System

displayed in the Aquarius stall, as well as the pit-less concept of the system.

There has been a flurry of orders, post the exhibition.

AADINATH INDUSTRIES, DELHI (Automatic Paint Sludge Removal)

Aadinath Industries is one of the leading names in offering quality services for Vacuum Metallizing & Plastic Injection Molding. They offer plating services on plastics, such as UV coating, etc. This is a Repeat Order that the customer has placed on Aquarius. The earlier system has been installed at their Kundli plant.

AQUARIUS is installing an Automatic Paint Sludge Removal System, HYDROFLOTY model 6M along with Automatic Chemical Dosing System, for their existing paint shop. AQUARIUS is already supplying Paint Booth Chemicals to their existing as well as new paint shops, which are giving excellent results for the special UV paints used by the customer. The HYDROFLOTY system will be directly connected to their existing paint booth, with no requirement of sludge pit.

The pit-less design of the Aquarius sludge removal system is being widely appreciated by our customers.

PUTZMEISTER INDIA PVT. LTD., KUNDAIM, GOA (Automatic Paint Sludge Removal)

PIPL manufactures state-of-art Concrete Pumps, Concrete Boom Pumps, Mobile Line Pumps and Stationary Boom Placers.

AQUARIUS is installing an Automatic Paint Sludge Removal System, HYDROFLOTY model 4M along with Automatic Chemical Dosing System, for their existing paint shop. AQUARIUS is also providing the required Paint Booth Chemicals. With the suggestions made by Aquarius for changes in th existing sludge pit, the sludge removal efficiency has increased substantial at PIPL.

RISHABA PVT. LTD, EGGATUR, TN (Automatic Paint Sludge Removal System)

Part of the Butterfly Group, the company was setup to cater to the export market demand of non-home appliance products. Currently the company manufactures Tableware and Kitchenware items and exports products to the European Union.

AQUARIUS is installing an Automatic Paint Sludge Removal System, HYDROFLOTY model 4M, at their Eggatur plant. The Zero Liquid Discharge Hydrofloty "Pitless" system is connected directly to 2 nos. Paint Booths, with no sludge pit. AQUARIUS is also providing the required Paint Booth Chemicals and a state-of-art Automatic Chemical Dosing System.

The paint shop is being supplied by Ace Coating India Pvt.Ltd.

NASH INDUSTRIES, SRIPERUMBUDUR, TN (Automatic Paint Sludge Removal System)

NASH group is a manufacturing solutions provider with capabilities of Design,

Precision Sheet Metal Stamping, Fabrication and Assemblies. Nash has in-house tool

room with design & manufacturing facilities as well as surface treatment & special processes available in-house.

AQUARIUS is installing an Automatic Paint Sludge Removal System, HYDROFLOTY model 4M,

at their Sriperumbudur plant, TN. The Zero Liquid Discharge Hydrofloty system is connected directly to 2 nos. Paint Booths,

with NO SLUDGE PIT. This PITLESS Hydrofloty system is with a special

Redelivery Station, as booths are at some distance from the system.

AQUARIUS is also providing the required Paint Booth Chemicalsand a state-of-art Automatic Chemical Dosing System.

CII SURFACE COATING 2022 SHOW, NEW DELHI

The CII Surface Coating Show 2022 at Delhi was a great success! The AQUARIUS stall had a wonderful response with prestigious clientele visits. The AQUARIUS "PITLESS" design of the Paint Sludge Removal System was very well appreciated (no civil sludge pits required) along with the state-of-art Solvent Recyclers.

In addition to the Hydrofloty Automatic Paint Sludge Removal Systems, the Solvent Recyclers and Centrifuge Separators also proved to be of major interest to the visitors.

TATA Hitachi Construction Machinery Company, Dharwad (Product: Automatic Paint Sludge Removal System)

Tata Hitachi is a leading name in manufacturing of construction equipment in India. They manufacture excavators, wheeled products, cranes, etc. This is the third Sludge Removal System that Aquarius is installing for Tata Hitachi. The earlier installations are at their Kharagpur and Dharwad plant.

AQUARIUS is installing the Zero Liquid Discharge Automatic Paint Sludge Removal System, HYDROFLOTY model 4M, for their new paint shop at Dharwad plant. The HYDROFLOTY system is connected to a centralized sludge pit. Paint sludge from 2 nos. Down Draft Painting Booths is collected in this sludge pit and automatically removed by the HYDROFLOTY system. Aquarius has worked closely with the paint shop supplier for a very innovative sludge pit configuration. AQUARIUS is also providing the required Paint Booth Chemicals and a state-of-art Automatic Chemical Dosing System. The Hydrofloty is a completely automatic Zero Liquid Discharge system and the customer will be drastically reducing his cleaning & maintenance costs, manpower costs as well as water costs in their new paint shop by installing the Automatic HYDROFLOTY Paint Sludge Removal System.

The new paint shop is being supplied by Parker Engineering India Pvt. Ltd., Gurugram, Haryana (NIHON PARKERIZING CO., LTD., JAPAN Group)

FOMAR CV Brakes India Pvt. Ltd., Sonipat, Haryana (Product: Automatic Paint Sludge Removal System)

FOMAR CV Brakes India is a producer of brake pads, lining and discs for passenger and commercial vehicles.

AQUARIUS is installing an Automatic Paint Sludge Removal System, HYDROFLOTY model 4M, at their plant in Kundli, in Haryana. The Zero Liquid Discharge Hydrofloty system is connected directly to 3 nos. Side Draft paint booths, thus avoiding the need of a sludge pit. The highlight of the project is the special design of the 3 nos. paint booths with a common water channel.

AQUARIUS is also providing the required Paint Booth Chemicals and a state-of-art Automatic Chemical Dosing System.

The paint shop is being supplied by TechExpert Engineering Pvt. Ltd., Pune.

Ansa Decoglass Pvt. Ltd. Kosamba, Gujarat (Product: Automatic Paint Sludge Removal System)

Asna is dedicated captive unit for Piramal Glass, They are pioneer of glass bottle coating in India with state-of-the-art decoration facility in India and Asia Pacific, which provides myriad glass decoration like printing, pad printing, UV coating, etc. They have clients like Coty, LVMH, Christian Dior, Yves Roche, etc.

AQUARIUS is installing the Zero Liquid Discharge Automatic Paint Sludge Removal System, HYDROFLOTY model 4M, , for their new U V Coating line at Kosamba factory. The HYDROFLOTY system is connected directly to 2 nos. Side Draft Paint Booths, thus avoiding a sludge pit, ensuring substantial savings in civil costs and reduction in pollution. The highlight of the project is an extended common water channel design for the 2 nos. paint booths. This booth design limits the sludge collection to the water channel, keeping the booths clean with easy & efficient removal of the paint sludge.

AQUARIUS is also providing the required Paint Booth Chemicals and a state-of-art Automatic Chemical Dosing System. The customer will be drastically reducing his cleaning & maintenance costs, manpower costs as well as water costs in their new paint shop.

Aquarius has worked closely with the paint shop supplier in establishing this system for the U V coating line.

The new UV Coating Line is being supplied by Shree Gajanan Steel Products, Mumbai.

Klassic Wheels Ltd., Ahmednagar (Product: Automatic Paint Sludge Removal System)

acity of over 11-million wheel rims per annum. This is a REPEAT ORDER by Klassic Wheels on Aquarius for Automatic Paint Sludge Removal System.AQUARIUS is installing a completely automatic system without sludge pit for Klassic Wheels, for their new paint shop in Ahmednagar. The system comprises of the Zero Liquid Discharge Automatic Paint Sludge Removal System, HYDROFLOTY model 4M, connected directly to 2 nos. Side Draft Paint Booths, thus avoiding a sludge pit and ensuring effective collection of sludge, substantial savings in civil costs, space and also reduction in pollution.

The system is so designed that it will continuously remove the paint sludge from the 2 booths alternately, returning the clean water back to the respective paint booth. Aquarius has worked closely with the paint shop supplier to establish a water channel design for the booths, which ensures high sludge collection efficiency in the booths and thus keeps the paint booths very clean.

AQUARIUS is also providing the required Paint Booth Chemicals and a state-of-art Automatic Chemical Dosing System. The customer will be drastically reducing his cleaning & maintenance costs, manpower costs as well as water costs in their new paint shop.

GABRIEL INDIA LTD. DEWAS, MP (Product: Automatic Paint Sludge Removal System)

Gabriel India is the flagship company of the ANAND Group. It is a trusted ride control products brand in India with products like shock absorbers, front forks, dampers and so on.AQUARIUS is installing an Automatic Paint Sludge Removal System, HYDROFLOTY model 4M, at their plant in Dewas, near Indore, in MP. The Hydrofloty system will be connected to the sludge pit of their upcoming new paint shop. The paint sludge will be collected from the sludge pit by a special floating suction device and sent to the Hydrofloty system for efficient separation, dewatering and sludge disposal. AQUARIUS is also providing the required Paint Booth Chemicals and a state-of-art Automatic Chemical Dosing System.

The Hydrofloty is a completely automatic Zero Liquid Discharge system and the customer will be drastically reducing his cleaning & maintenance costs, manpower costs as well as water costs in their new paint shop, by installing the Automatic Hydrofloty Paint Sludge Removal System.

EXPORT ORDER FROM QUIN GLOBAL, AUSTRALIA (Product: Solvent Recovery System)

Quin Global is a worldwide manufacturer of adhesives and tool systems. It is the world’s largest spray cannister adhesive manufacturer, with an expansive product line of over 300 unique adhesive products.Quin Global uses many solvents in their production of adhesives, including Methylene Chloride, Acetone, Hexane, etc. AQUARIUS is providing the advanced Solvent Recovery System, model ALFA 120 to effectively recycle the dirty solvents produced during the manufacturing process.

AQUARIUS is also providing a state-of-art Automatic Solvent Loading System, which will help the customer to automatically load the dirty solvents in the Solvent Recovery System, without causing any overflows. The recycled solvents will be used by the customer for cleaning applications, etc., thus bringing down their yearly solvent costs substantially.

KOMATSU INDIA PVT. LTD, ORAGADAM, TN (Product: Automatic Paint Sludge Removal System)

Komatsu is a global leading manufacturer of construction, mining and forestry equipment as well as forklift and industrial machinery. Komatsu India manufactures dumper trucks, wheel loaders, bulldozers, hydraulic excavators, etc.Komatsu India’s Oragadam plant in Tamil Nadu has an existing, large down draft painting booth with a civil water tank underneath the booth. Aquarius is providing the advanced Automatic Paint Sludge Removal System, HYDROFLOTY model 6M to effectively remove the paint sludge, continuously, from the civil booth tank.

AQUARIUS is also providing the required Paint Booth Chemicals and a state-of-art Automatic Chemical Dosing System.

Komatsu India will now benefit from the HYDROFLOTY installation with the automatic & efficient removal of the paint sludge from the pit, without any manual intervention. Furthermore, the system will ensure savings in water, maintenance, labor and cleaning costs.

The paint shop refurbishment is being done by Vitech Enviro Systems, Chennai.

FLEETGUARD FILTERS PVT. LTD., NANDUR (Product: Automatic Paint Sludge Removal System)

FLEETGUARD-FILTRUM designs and manufactures Air Oil Separators (AOS) specific to application requirement in rotary screw compressors. Fleetguard Filters is a preferred supplier to the Automotive and Industrial OEMs.FLEETGUARD-FILTRUM designs and manufactures Air Oil Separators (AOS) specific to application requirement in rotary screw compressors. Fleetguard Filters is a preferred supplier to the Automotive and Industrial OEMs.

AQUARIUS is installing an Automatic Paint Sludge Removal System, HYDROFLOTY model 4M, at their plant in Nandur, in Maharashtra. The Hydrofloty system is connected directly to the side draft paint booth, with the help of a special suction device, thus avoiding the requirement of a sludge pit. AQUARIUS is also providing the required Paint Booth Chemicals and a state-of-art Automatic Chemical Dosing System. The Hydrofloty is a completely automatic Zero Liquid Discharge system and the customer will be drastically reducing his cleaning & maintenance costs, manpower costs as well as water costs in their new paint shop, by installing the Automatic Hydrofloty Paint Sludge Removal System.

The paint shop is being supplied by Ace Coating India, Pune.

TATA Hitachi Construction Machinery Company, Dharwad (Product: Automatic Paint Sludge Removal System)

Tata Hitachi is a leading name in manufacturing of construction equipment in India. They manufacture excavators, wheeled products, cranes, etc. This is the second order from Tata Hitachi on Aquarius. The earlier order was for their Kharagpur plant.AQUARIUS is installing an Automatic Paint Sludge Removal System, HYDROFLOTY model 4M, for their new paint shop. The Hydrofloty system is connected directly to 2 nos. paint booths, thus avoiding the requirement of a sludge pit. AQUARIUS is also providing a state-of-art Automatic Chemical Dosing System. The Hydrofloty is a completely automatic Zero Discharge system and the customer will be reducing his cleaning & maintenance costs, manpower costs as well as water costs drastically in their new paint shop by installing the Automatic Hydrofloty Paint Sludge Removal System.

The new paint shop is being supplied by Soham Surface Coatings Pvt. Ltd., Pune.

Uttam Polyrubs India Pvt. Ltd., Bhiwadi (Product:Solvet Recovery System)

Uttam Polyrubs is a leading global supplier in the footwear manufacturing segment for Neolite/Rubber sheets for footwear soles, TPR Soles & Sheets, EVA Injection Soles, TPU Soles, Rubber Moulded Soles.Uttam Polyrubs was in need of a Solvent Recovery System for cleaning of dirty solvents as well as water-based waste material coming from their manufacturing process. The Solvent Recovery System will help them to reuse the solvents and also for easy disposal of the waste water. AQUARIUS is installing a Solvent Recovery Unit, model ALPHA 10 at their Bhiwadi factory. Aquarius is also providing a Vacuum Generator to make it possible to clean high boiling point solvents, at reduced running costs. Safe recycling of solvents requires state-of-art equipment, which is reliable and safe and has been designed and built with skill, in strict compliance with CE, ATEX, and has also undergone extensive safety testing. AQUARIUS is supplying a Solvent Recovery Unit with electrical system ATEX EX II 3G suitable for installation in Zone 2. ATEX EX II 2G (explosion proof for hazardous atmospheres) units are also available, suitable for installation in Zone 1.

AQUARIUS is also supplying special Thermo Resistant Bags to ensure that the operator never comes in direct contact with solvents and/or distillation residues.

KINECO LTD., GOA (Product: Solvent Recovery Unit)

Kineco is one of the leading names in India in the composites industry, offering a wide range of products and processing technologies to customers all over the world.Kineco was in need of a Solvent Recovery System for recycling of dirty solvents, like Acetone, etc., which they get after using in their manufacturing process. AQUARIUS is installing a Solvent Recovery Unit, model ALPHA 70 at their Goa factory. Safe recycling of solvents requires state-of-art equipment, which is reliable and safe and has been designed and built with skill, in strict compliance with CE, ATEX, and has also undergone extensive safety testing. AQUARIUS is supplying a Solvent Recovery Unit with electrical system ATEX EX II 3G suitable for installation in Zone 2. ATEX EX II 2G (explosion proof for hazardous atmospheres) units are also available, suitable for installation in Zone 1.

AQUARIUS is also supplying special Thermo Resistant Bags to ensure that the operator never comes in direct contact with solvents and/or distillation residues.

ORDNANCE FACTORY, KANPUR (Product: Paint Sludge Separator)

Ordnance Factory Kanpur is one of the 41 Ordnance factories under the aegis of Ordnance Factory Board(OFB). The factory manufactures ordnances, spare barrels and other spares for all Artillery and Tank guns.Aquarius is installing a Paint Sludge Separator, which is directly connected to 2 nos. paint booths. The Separator system will continuously remove the paint sludge from the two booths and send back clean water to the booths. Aquarius will also be providing the required Paint Booth Chemicals for the efficient working of the system.

The paint shop is being supplied by M/s Crescent Techno Solutions, Greater Noida.

JOHN DEERE INDIA PVT LTD, SANASWADI PUNE (Product: Automatic Paint Sludge Suction System)

John Deere Is one of India’s leading tractor manufacturers offering a wide range of tractors, combine harvesters, implements and other agriculture equipment.John Deere had been facing a problem with their existing sludge removal system. AQUARIUS is installing an Automatic Paint Sludge Suction System, which will be integrated with their existing set-up. Removing paint sludge, collected in a sludge pit, has always been a challenging task. Aquarius uses the latest state-of-art technology to effectively bring together the sludge in the pit and automatically transfer it to the sludge removal system. Thorough removal of paint sludge from the sludge pit means savings in cleaning & maintenance costs of the paint booths & sludge pit as well as savings in water cost.

MEGA KLC POLYMER TECHNOLOGIES PVT LTD, PUNE (Product: Automatic Paint Sludge Removal System)

Mega KLC Polymer Technologies is located in Mhalunge, Pune. They manufacture a wide range of plastic parts, including plastic auto components.AQUARIUS is installing an Automatic Paint Sludge Removal System, HYDROFLOTY model 4M, for their new paint shop. The Hydrofloty system is connected directly to the Paint booths, thus avoiding the requirement of a sludge pit. AQUARIUS is also providing a state-of-art Automatic Chemical Dosing System. The Hydrofloty is a completely automatic Zero Discharge system and the customer will be reducing their cleaning & maintenance costs, manpower costs as well as water costs drastically in their new plant.

The paint shop is being supplied by M/s Prism Surface Coating Systems Pvt. Ltd., Bangalore.

In addition to above system orders, AQUARIUS is now supplying their Fast Acting, Special Paint Booth Chemicals to a host of customers who are now able to remove their paint sludge much more effectively and at lower costs.

SHRI ASHTAVINAYAK GLASS PVT. LTD., TAL. KHANDALA, SATARA (Product: Glass Fines Separator)

Shri Ashtavinayak Glass Private Limited, or S A Glass as they are known, are supplying and exporting a comprehensive array of Float Glass , including Toughened Glass, Laminated Glass, Insulated Glass, Ceramic Frit Glass, Heat Strengthened Glass, Security Shield Glass and Sound Proof Glass.Aquarius is installing a Glass Fines Separator , with a special pump, in their new expansion plant. The Separator, pump as well as the controls are trolley mounted , in a compact design. The Separator will be used to clean the glass fines from 5 nos. glass processing machines.

The Separator can separate the glass fines from the coolant water at a very high efficiency for particle sizes down to 5 microns and below, on a continuous basis.The Separator will help S A Glass to reduce their machine maintenance costs as well as water costs substantially.

VEDIA SOLUTIONS – A Division of LAXMI DENTAL EXPORTS PVT. LTD., MUMBAI (Product: Solvent Recovery Plant)

Laxmi Dental Export Private Limited is a full service and well equipped dental lab specializing in providing finest dental products and services. They provide metal ceramic crowns & bridges, framework for removable prosthetics and other dental prosthesis.Their process requires use of various solvents. Disposal of dirty solvents had become a major problem for the customer. Added to this, they had to purchase fresh solvents for their regular production as well as cleaning requirements.

Aquarius is installing a compact Solvent Recovery Unit, model ALPHA 50 for efficient cleaning of their solvents so that the solvents can be reused. This will not only overcome the need of dirty solvents disposal, but also save money as there will be drastic reduction in buying of fresh solvents.

BASF - Coatings Division, Mangalore (Product: Automatic Solvent Recovery Plant)

BASF is one of the largest chemical producers in the world, operating from over 80 countries. BASF has twelve divisions grouped into six segments. The Coatings Division of the BASF Group develops, produces and markets a high-quality range of innovative automotive OEM coatings, automotive refinishes as well as decorative paints.

AQUARIUS is installing a state-of-art Automatic Solvent Recovery Plant, model MAV 500 EEXD Atex EX II 2G Zone 1 in collaboration with IRAC Tech Srl, Italy. The recovery plant has a capacity of processing max. 140 liters per hour of dirty solvents.

Right from the loading of dirty solvents upto the recovery of clean solvents and collection of the residues, the plant is completely automatic.

A specially designed vacuum distillation system, with liquid ring pump, is provided to speed up the distillation process and reduce risks of exothermic reactions. For condensation, the cooling level is maintained constant with the use of air and chilled water.

A special “Memo System” is also provided to monitor each operation cycle of the plant as well as to allow action on the machine program directly from the manufacturer’s factory.

KLASSIC WHEELS, AHMEDNAGAR (Product: Automatic Paint Sludge Removal System)

Klassic Wheels is a global automotive steel wheel rim manufacturer having capacity of over 11 million wheel rims per annum. They manufacture steel rims for 2 wheeler, 3 wheeler and 4 wheeler vehicles.AQUARIUS is installing an Automatic Paint Sludge Removal System, HYDROFLOTY model 9M, for their paint shop in the new plant being installed in Ahmednagar. The paint shop has 2 nos. down draft paint booths with a centralized sludge pit. The HYDROFLOTY system is connected to the sludge pit.

AQUARIUS is also providing the required Paint Booth Chemicals and an Automatic Chemical Dosing System. The Hydrofloty is a completely automatic Zero Discharge system and Klassic Wheels will be reducing their cleaning & maintenance costs, manpower costs as well as water costs drastically, as compared to their existing plant.

ACT PLAST PAINTS, CHENNAI (Product: Automatic Paint Sludge Removal System)

Act Plast Paints is a manufacturer of OEM parts & assemblies and achieved a niche in the field of automotive parts with specialization in Injection Molding, Spray Painting, Laser Marking, Pad Printing etc. They have two units in Chennai and one near Puducherry. Presently, they are putting up a new plant in Anantapur, Andhra Pradesh.AQUARIUS is installing an Automatic Paint Sludge Removal System, HYDROFLOTY model 9M, for their paint shop in the new plant. The new paint shop has 3 nos. side draft paint booths with a centralized sludge pit. The HYDROFLOTY system is connected to the sludge pit. AQUARIUS is also providing the compact sludge pit design suited for the Hydrofloty system.

Aquarius will be supplying the required Paint Booth Chemicals and an Automatic Chemical Dosing System for the new paint shop.

AADINATH INDUSTRIES, DELHI (Product: Automatic Paint Sludge Removal System)

Aadinath Industries is one of the leading names in offering quality services for Vacuum Metallizing as well as Plastic Injection Molding.They offer plating services on plastics, such as ABS and PP.AQUARIUS is installing an Automatic Paint Sludge Removal System, HYDROFLOTY model 4M, for their new paint shop. AQUARIUS is already supplying Paint Booth Chemicals to M/s Aadinath for their existing paint shop, which are giving excellent results for the special UV paints used by the customer. The new paint shop has 3 nos. paint booths with a centralized sludge pit. The HYDROFLOTY system is connected to the sludge pit. AQUARIUS is also providing the required Paint Booth Chemicals and an Automatic Chemical Dosing System for the new paint shop.For space saving, as well as for easy collection and transfer of the collected paint sludge, the HYDROFLOTYSystem is placed over the sludge pit.

The design for the sludge pit is also provided by AQUARIUS, as the UVpaints need special handling for effective separation of the paint sludge.

SURFACE COATING SHOW 2019, NEW DELHI

Aquarius Environmental Division had participatedin the SURFACE COATING EXPO 2019 at the India Habitat Centre, New Delhi, which was held on 28th& 29th November 2019.The stall was jointly put up with our collaborators viz. STA GmbH, Germany, who areworld leaders in the manufacture of a wide range of Centrifuge Separators.

Aquarius also highlighted the product range of its other collaborators viz. Paint Sludge Removal Systems & Chemicals of Hydro Italia, Italy as well as the Solvent Recovery Systems of IRAC Tech, Italy.

There was a good interaction with the delegates attending the 2-day conference as well as with the clients visiting our stall. Additionally, various requirements could be discussed with the esteemed paint shop suppliers at the exhibition. The conference and exhibition wasa good gathering of the surface coating family.

ENDURANCE TECHNOLOGIES LTD PUNE (Product: Automatic Paint Sludge Removal System)

Endurance Technologies is one of India's leading Automotive component manufacturing companies. It is the largest aluminium die casting manufacturer in India and one of the leading automotive component manufacturers in Aluminium die casting, including alloy wheels, suspension, transmission and braking systems.AQUARIUS is installing an Automatic Paint Sludge Removal System, HYDROFLOTY model 9M, for their existing paint shop. Endurance was removing the paint sludge manually from their sludge pit, which proved to be very messy and tedious. This also caused frequent pump choking and regular break-downs. The present sludge pit will now be slightly modified and the HYDROFLOTY System will be connected to it. AQUARIUS is also providing the required Paint Booth Chemicals and an Automatic Chemical Dosing System. For space saving, as well as for easy collection and transfer of the collected paint sludge, the HYDROFLOTY System is placed over the sludge pit.

In addition to effective & automatic removal of paint sludge, Edurance will save space near the sludge pit, which they will use for storage, etc

POLYPLASTICS INDUSTRIES, BAWAL (Product: Refurbishment of Existing Skimmer System)

This is the 6th consecutive order from Polyplastics. The customer had 2 nos. conventional skimmer systems installed at their automatic paint shop for paint sludge removal. However, both the systems were not functional for some time, thus leading to excessive sludge build-up in the paint booths, as well as regular maintenance hassles.AQUARIUS has upgraded the conventional skimmers and made them functional. This involved the up-gradation of the system in terms of technology as well as parts. AQUARIUS is also providing the required Paint Booth Chemicals and Automatic Chemical Dosing System for the upgraded skimmer system.

FAIRFIELD ATLAS LTD (DANA GROUP), BELGAUM (Automatic Paint Sludge Removal System)

Fairfield Atlas Limited, a DANA Group company, is primarily engaged in manufacturing and selling of automotive transmission gears and gear boxes.AQUARIUS is installing an Automatic Paint Sludge Removal System, HYDROFLOTY model 4m, in their existing paint shop supplied by Eisenmann. The HYDROFLOTY system will be connected to their existing sludge pit. Few modifications will be done to the sludge pit to make it more suitable for efficient collection of the paint sludge by the HYDROFLOTY. AQUARIUS is also providing the required Paint Booth Chemicals and the special Dosing System.

To save space, the compact HYDROFLOTY system will be installed over the sludge pit with a movable sludge trolley on the side.

WALTON HI-TECH INDUSTRIES LTD., BANGLADESH (Product: Oil Cleaning Separator)

Export order received from Walton Group, which is the latest multinational electrical, electronics, automobiles and other appliances brand, carrying out its production through different subsidiaries under the banner of Walton Group with headquarter in Bangladesh.Aquarius is installing an Oil Cleaning Separator for one of their Niehoff Wire-Drawing lines in Gazipur, Bangladesh. The Separator is provided for the on-line filtration of the lubricant oil. The Separator cleans the oil at a very high efficiency for particle sizes up to 5.0 microns and below on a continuous basis.

DANA GRAZIANO TRANSMISSIONI INDIA, SANAND (Product: Automatic Paint Sludge Removal System)

This is a repeat order from DANA, for their plant in Sanand. The earlier order was for an Automatic Paint Sludge Removal System at their plant in Chandgad (near Belgaum). The Sanand plant manufactures automotive axles.AQUARIUS is installing an Automatic Paint Sludge Removal System, HYDROFLOTY model 9m, for their new paint shop. The system is connected to a centralized sludge pit. AQUARIUS is also providing the required Paint Booth Chemicals and Automatic Chemical Dosing System.

The paint shop is being supplied by M/s Electrocoat Equipments (I) Pvt. Ltd., Pune.

ORDNANCE FACTORY AMBAJHARI, NAGPUR (Product: Paint Sludge Separator System)

OFAJ is engaged in the manufacture of Ammunition Hardware viz. shells, cartridge cases, etc. and fabrication of floating & manually launched assault bridges.Aquarius is installing a Paint Sludge Separator, which is directly connected to the Robotic paint booth as well as the Touch-up paint booth. The Separator system will continuously remove the paint sludge from the two booths and send back clean water to the booths. Aquarius is also providing the required Paint Booth Chemicals for the efficient working of the system.

The paint shop is being supplied by M/s Crescent Techno Solutions, Greater Noida.

ESSAR STEELS, PUNE: (Product: Solvent Recovery System)

Essar Steels, Pune (earlier Shree Precoated Steels plant) manufactures color coated coils and export to more than 100 countries.Essar Pune plant was facing a problem on disposal of dirty solvents. Added to this, they had to purchase additional solvents for their regular production as well as cleaning requirements.

Aquarius is installing a compact Solvent Recovery Unit, model ALPHA 20 for efficient cleaning of their solvents so that the solvents can be reused. Additionally, a Vacuum Generator is provided to allow cleaning of high boiling point solvents, at a lower temperature, thus saving on energy.

WEIR BDK VALVES, HUBBALI (Product: Automatic Paint Sludge Removal System)

Weir BDK Valves is a leading provider of flow control solutions to varied industries. The BDK valves are globally recognized.This is a repeat order from the customer. AQUARIUS is installing the state-of-art Automatic Paint Sludge Removal System, HYDROFLOTY model 4m, in their new expansion paintshop project. AQUARIUS is also providing the required Paint Booth Chemicals along with a special Dosing System.

In the new paintshop, paint sludge from 2 nos. side draft paint booths will be directly removed by the HYDROFLOTY system. Clean water will be returned back to the respective booths, thus helping to keep the booths & pipelines clean. The HYDROFLOTY system also ensures savings in Space, Water, Cleaning & Maintenance costs as well as Disposal costs.

The paint shop is being supplied by VITECH ENVIRO SYSTEMS, CHENNAI.

Indian Surface Treatment & Finishing Expo (ISTF) Delhi

The theme of the AQUARIUS stall at the recently held ISTF Expo 2019 at Pragati Maidan Delhi was “Eco-Friendly Productivity with Enhanced Savings!”The stall was jointly put up with IRAC Tech Italy, who is one of the leading manufacturers of a wide range of Solvent Recovery Systems. Aquarius represents the complete range of IRAC systems in India. An ALPHA 15 Solvent Recycler was exhibited in the Aquarius stall, which generated lot of attention and interest amongst the visitors. There was good interaction with the clients visiting the Aquarius stall regarding their various requirements.

The exhibition was very much successful with participation of manufacturers of paint shops, electroplating plants, water treatment plants & accessories, etc., which proved interesting for the visiting clientele.

Visit us at ISTF Expo 2019 at Pragati Maidan, New Delhi

One of India’s largest exhibition on Surface Treatment & Finishing Technologies is taking place on 5th, 6th, 7th September 2019 at Hall No.7,PragatiMaidan, New Delhi.Indian Surface Treatment & Finishing Expo offers an interactive platform for our clients to understand our wide range of products related to the Surface Coating & Environmental fields.

AQUARIUS is participating in the ISTF Expo 2019 to highlight its Complete Range of Automatic Paint Sludge Removal Systems, Paint Booth Chemicals, Centrifuge Separators for Solid-Liquid Separations and Solvent Recovery Systems. This year we willbe exhibiting the ALPHA Series Solvent Recovery Unit, to highlight its special features.

To offer the latest in technology, we are proud to partner with Hydro Italia Srl Italy, STA GmbH Germany and IRAC Tech Srl Italy.

We will be happy to discuss your requirements, including Paint Sludge Removal, Phosphate Sludge Removal, Paint Booth Chemicals, Solvent Recovery, Solid-Liquid Separations & Dewatering, Oil & Coolant Cleaning, Waste Water Treatment, etc. at our stall.

We welcome you to visit our Stall no. IE-52 for more information about our product range.

Automatic Centrifuge Separator System @ SECO TOOLS INDIA (P) LTD., PUNE

Seco, a part of the Sandvik Group, is one of the world’s largest providers of comprehensive metal cutting solutions for milling, stationary tools, hole-making and tooling systems.Seco has placed an order on Aquarius for Automatic Separator System, model A-25, for the separation of Aluminium Oxide powder from water. A similar system was installed by Aquarius at Sandvik Asia Pune plant in 2018. The Al Oxide powder is used in grinding processes as an abrasive, due to its hardness & strength.

The Al oxide slurry, after the process, was being stored in an underground collection pit, leading to ineffective powder separation, manual cleaning and wastage of water. The powder slurry is now collected in an overhead tank. The Separator gets activated when the centralized tank gets filled-up. The slurry is efficiently cleaned by the Separator and the cleaned water is collected in reservoir for reuse. The Separator shuts-off when the slurry in the tank reaches the low level. The Al oxide powder slurry is cleaned efficiently, the dewatered powder is collected and the clean water is reused. Thus effectively reducing the load on ETP and ensuring savings in water and powder recovery.

Automatic Paint Sludge Removal System @ POLYPLASTICS INDUSTRIES (INDIA) PVT. LTD., DASLANA GUJARAT

This is the fifth repeat order from PolyplasticsIndustries for Paint Sludge Removal System. AQUARIUS is installing the state-of-art Automatic Paint Sludge Removal System, HYDROFLOTY model 6m at their Daslana Plant.Aquarius is also providing the required Paint Booth Chemicals along with a special Dosing System.

TheSludge Removal System is connected to a small centralized sludge pit for continuous removal of paint sludge.Clean water will be returned back to the paint booths, thus helping to keep the booths & pipe lines clean. An in-built “auto-cycle” feature ensures removal of residual paint sludge, collected in the pit, even after the paint shop stops operation. The HYDROFLOTY system ensures savings in Space, Water, Maintenance costs as well as Disposal costs and keeps the paint booths clean.

We hope the above information was interesting for you. We will be happy to assist you in any of your Solid-Liquid separation requirements including Paint & Phosphate Sludge Removal, Oil & Coolant Cleaning, Solvent Recovery, Chemicals, Sludge Dewatering, etc.

Automatic Paint Sludge Removal System @ Jamna Auto, Malanpur

This is the third repeat order for Jamna Auto. The first & second installations were at their Jamshedpur and Yamunanagar plants respectively.A completely Automatic Paint Sludge Removal System will be installed in their new paint shop at Malanpur plant. It will be connected to a very compact sludge pit, specially designed for DD Paint Booth. The system comprises of a HYDROFLOTY model 6M, floating suction system with submersible pump, automatic dosing system, a PLC based control panel as well as the required Chemicals.

The paint sludge from the paint booth is continuously treated by the on-line chemical dosing system. The treated paint sludge is efficiently separated by the HYDROFLOTY System and clean water returns back to the pit.

The customer has saved a considerable space by opting for a compact pit with the HYDROFLOTY system. Moreover, there will be considerable savings in water costs as well as savings in the cleaning and maintenance costs, due to the high efficiency sludge removal.

The new paint shop is being supplied by Surfin Coating Systems, Pune.

Spicer India Pvt. Ltd. Satara

Spicer India Priavte Limited designs and manufactures axles, driveshafts and drivetrain products for the OEMs of utility vehicles and commercial vehicles. It is a joint venture of ANAND Group with Dana Incorporated.The Spicer plant at Satara was facing a problem of consuming too much space by drying beds of their ETP. Moreover, the sludge required a considerable time for drying inside these drying beds. As the production increased, sludge drying became a bottle neck in the process.

After studying the various streams coming to the ETP, AQUARIUS suggested a Semi-Automatic Sludge Separator System. This system will be connected to Spicer's existing settling tank. The sludge will be dewatered in the Separator and the cleaned water will be reused.

Additionally, AQUARIUS will also be supplying suitable Chemicals for the proper treatment of the sludge slurry prior to dewatering. Spicer will be utilizing the space, freed by their present sludge drying beds, for storage purpose and for other utilities.

We hope the above information was interesting for you. Please do let us know if we can be of assistance to you in any of your requirements including Paint & Phosphate Sludge Removal, Oil & Coolant Cleaning, Solid-Liquid Separations, Chemicals, Solvent Recovery Systems, etc.

AUTOMOTIVE AXLES LTD., MYSORE

Axles India is a leading manufacturer of axle housings in South India. They are putting up a new manufacturing plant in Mysore with the latest technology.AQUARIUS is providing them with the state-of-art Automatic HYDROFLOTY System for the continuous separation and removal of paint sludge. This system will require a drastically reduced sludge pit size! Moreover, very clean water is returned back to the paint booths, thus keeping the booths clean. The HYDROFLOTY system ensures savings in Space, Water, Maintenance as well as Disposal costs.

The HYDROFLOTY System is designed to automatically clean the small pit connected to 2 nos. DD paint booths. Fast-Acting Hydro Chemicals will be dosed usingAutomatic Dosing Systems. The equipment will give feedback to customer’s SCADA system.

The new paint shop is being provided by Electrocoat Equipments, Pune.

TATA Hitachi Construction Machinery Company Private Limited, Kharagpur

Tata Hitachi is the leader in construction equipment in India. They manufacture excavators, wheeled products, cranes, etc.The Paint Sludge Separator System is a part of the new paint shop. The system comprises of a Centrifuge Paint Sludge Separator connected directly to 2 nos. Side Draft paint booths, thus avoiding the need of sludge pit completely. The Separator will continuously remove and dewater the paint sludge from the paint booths. The paint shop has advanced features to ensure efficient painting and cleanliness during painting operations. The new paint shop is being provided by Soham Surface Coatings, Pune.

Epiroc Mining Equipment Ltd, Hyderabad

Epiroc is a Swedish company active in the mining, infrastructure and natural resources industries. Epiroc produces innovative drill rigs, rock excavation and construction equipment.For their exiting paint shop, Aquarius is providing a Centrifuge Paint Sludge Separator. The Separator will continuously clean 2 nos. Side Draft paint booths. A manual change over arrangement is provided to the Separator along with an advanced Automatic Chemical Dosing System & Chemicals.

We hope the above information was interesting for you. Please do let us know if we can be of assistance to you in any of your requirements including Paint & Phosphate Sludge Removal, Oil & Coolant Cleaning, Solid-Liquid Separations, Chemicals, etc.

Surface & Coating Expo 2018

The theme of the AQUARIUS stall at the recently held Surface & Coating Expo 2018 was “We Believe In Constant Innovation!”The stall was jointly put up with HYDRO ITALIA , to announce Aquarius tie-up with HYDRO ITALIA for their wide range of Chemicals & Systems for the Indian market. The exhibition had a good response and Mr Gianfranco Verona from HYDRO ITALIA was also invited as one of the speakers for the 2-day conference held during the exhibition.

There was a good interaction with the clients visiting the Aquarius stall, on their requirements like Paint Booth Chemicals, Paint Sludge Removal Systems, Oil & Coolant Cleaning Separators, Water & Waste Water Treatment Plants, Solvent Recovery Systems and so on.

Al Oxide Powder Separation Project At Sandvik Asia, Pune

The Separator is used for a special application viz. separation of Aluminium Oxide powder from water. The Al Oxide powder is used in grinding processes as an abrasive, due to its hardness & strength.The Al oxide slurry, after the process, was being discarded to the ETP. This increased the load on the ETP and also amounted to a lot of water wastage. The Separator System is provided with a centralized collection tank. Al oxide slurry, from the process, is collected in this tank. The Separator gets activated when the centralized tank gets filled-up. The slurry is efficiently cleaned by the Separator. The Separator shuts-off when the slurry in the tank reaches the low level.

The Al oxide powder slurry is cleaned efficiently, the dewatered powder is collected and the clean water recycled for process use. Thus effectively reducing the load on ETP and ensuring savings in water and powder recovery.

Paint Sludge Removal Project At Faiveley Transport Rail Technologies, Hosur

Faiveley is a part of the US based Wabtec Corporation, which is a leading supplier of technology-based products for freight rail, passenger transit and select industrial markets worldwide.Faiveley has an existing paint shop with a sludge pit for paint sludge collection. The sludge pit is located outside the shop floor, at some distance away from the paint shop. It was very cumbersome to remove the paint sludge manually from the deep sludge pit. Aquarius provided a special arrangement to pump the sludge to the ground level and subsequently to dewater it with the Separator system.

The suggested system will help Faiveley to clean the sludge pit with ease and also to reduce their costs on cleaning, disposal and maintenance work substantially.

Repeat Order for Pit-less Paint Sludge Removal System at Jamna Auto Industries

Conventionally, a multi-booth paint shop would normally have a centralized sludge pit for sludge collection. Among other problems, the sludge pit added to the maintenance woes, amounted to substantial civil cost, created pollution hazard and occupied lot of space. The trend today is to have paint shops without any sludge pits.At Jamna Auto, the Paint Sludge Separator Systems are a part of the new paint shops coming up at Jamshedpur and Yamunanagar. The compact system is connected directly to 2 nos. paint booths. The Separator cleans the paint booths individually and the sludge is dewatered effectively.

Greaves Cotton Ltd., Pune : GCL has an existing paint shop for their Diesel Engine Unit. Presently, the removal of paint sludge from the paint booths is done manually and quite tedious. Also, they have a requirement of cleaning used oil at times.

Aquarius is providing a“Trolley mounted Separator System” that can be used for removal of paint sludge as well as for cleaning of oil. The Separator can be easily moved to various locations in the shop floor.

Kirloskar Oil Engines Ltd., Kagal : The state-of-art factory at Kagal has a paint shop with a sludge pit set-up. The sludge pit is located outside the shop floor. The suggested system will help KOEL to reduce their cleaning, disposal and maintenance costs substantially. The Paint Sludge Separator System will be connected to the sludge pit using an intermittent OF tank system.

Aquarius Signs Collaboration Agreement with HYDRO ITALIA!

HYDRO ITALIA produces Plants as well as Chemicals for water and wastewater treatment, including paint sludge removal, demineralization, effluent treatment, biological treatment, etc.HYDRO ITALIA, which has got a long experience in the field of surface treatment, is particularly appreciated for its innovations in the field of waste water coming from paint booths.

You are welcome to visit HYDRO ITALIA website for a better understanding of their activities: http://www.hydroitalia.com.

With our added product range, we are more than keen to assist you in any of your sludge removal & chemical treatment requirements. Do let us know.

3 Booth Auto-Separator Installation at Parker Hannifin, Mumbai

Parker is the global leader in motion and control technologies, providing precision-engineered solutions for a wide variety of mobile, industrial and aerospace markets.The Separator System is designed to clean 3 nos. paint booths automatically. Cleaning time for each booth can be set, based on production load. The system cleans the booths automatically, one after the other, and stops for manual sludge emptying. The separator system also helps to avoid conventional sludge pit and its related maintenance problems.

Visit us at Surface & Coating Expo 2018

AQUARIUS and HYDRO ITALIA are jointly participating in the Surface & Coating Expo 2018 to be held at Chennai Trade Centre from 31st August to 2nd September 2018.All types of sludge removal and water treatment enquiries will be discussed at our stall including Paint Sludge Dewatering, Phosphate Sludge Removal, Chemicals, Wastewater Treatment, ETP, etc.

You are welcome to visit our Stall no. 95 for more information about our product range

Kirloskar Oil Engines Ltd., Kagal:

The state-of-art factory at Kagal has a paint shop with a sludge pit set-up. The sludge pit is located outside the shop floor. The suggested system will help KOEL to reduce their cleaning, disposal and maintenance costs substantially. The Paint Sludge Separator System will be connected to the sludge pit using an intermittent OF tank system.

Varroc Polymers Order for Automatic Paint Sludge Separator A-25

Varroc Polymers has placed an order for a completely Automatic Paint Sludge Separator System for their new plant in Chakan.The new paint shop, being put up by M/s Plustech Systems, has a centralized sludge pit. A special floating suction device is provided in the sludge pit for effective collection of the floating paint sludge. The sludge is pumped to an overhead overflow tank. The sludge concentration is increased in the overflow tank. Subsequently, the paint sludge from the overflow tank is pumped to the Automatic Separator.

The sludge is separated from the water at a very high efficiency and also dewatered effectively in the Separator. The dried sludge is automatically removed into a collection trolley. The clean water is returned to the sludge pit.

The separator has advanced HMI system and the PLC controls are with required system safeties in-built. The control panel is connected to the SCADA system of the customer.

New Overflow Tank Design for Paint Sludge Pits

A new Overflow (OF) Tank has been designed for the efficient collection and concentration of the paint sludge from the sludge pit, which can be easily pumped to a centrifuge separator.The OF tank is designed for those sludge pits, which do not have a skimmer tank or de-sludger system attached to it. Unlike skimmers, the OF tank does not have a skimmer arm and the sludge is allowed to float inside the tank. The trapezoid shaped tank is so designed to collect the floating paint sludge at one end, with the help of a specially designed suction device. The sludge is pumped to the centrifuge separator through this suction device.

The paint sludge sent to the centrifuge separator gets effectively dewatered and the clean water is sent back to the sludge pit.

‘Think Blue. Factory’ award for Volkswagen India Pune Plant, with major contribution of Centrifuge Separators

Volkswagen India, (Pune) plant has received the prestigious ‘THINK BLUE. FACTORY’ award for the greatest progress in waste reduction.One of the main measures contributing to this reduction was the recycling of paint sludge. This reduction was achieved by cutting down the moisture content from paint sludge using centrifuge Paint Sludge Separator.

As compared to the base value of 2011, VW India Pune plant has been able to reduce specific ‘Waste Generation’ by 30.5%.

Volkswagen Pune Plant, one of the 27 Volkswagen automotive manufacturing facilities worldwide, follows the ‘Think Blue. Factory.’ initiative to achieve environment-friendly manufacturing. Through this initiative, Volkswagen aims at reducing the impact of its manufacturing process on the environment by 25% per car globally through its participating facilities.

Three years into the program, the Pune plant has already surpassed the set target in the area of ‘Waste Generation’ and is close to achieving its targets in the areas of ‘CO2 Emissions’ and ‘Energy Consumption’. Rounding off the fruitful results of Volkswagen India was the consistent progress shown in the area of ‘Water Consumption’. Amongst the five key measurable areas, maximum reduction has been achieved in the area of ‘Waste Generation’.

Click here for more information - 'Think Blue. Factory'

bC India Conexpo Show, Greater Noida

The theme of the AQUARIUS stall at the recently held Bauma Conexpo Show, at Greater Noida Delhi, was “Proud to be Indian, Powered to be Global!”The exhibition had a good response but the highlight of the event proved to be the visit of Hon. Shri. Manohar Parrikar, Defence Minister of India, to the Aquarius stall. Apart from the construction equipment, Mr. Parrikar showed a great intrest in the Centrifuge Separator product range. “The Aquarius equipment exhibited is very techno-savvy,” commented Mr. Parrikar.

There was a good interaction with the visiting clients on their requirements like Hydraulic Oil cleaning, Paint Sludge Dewatering, etc.

Glasstec

STA had participated in glasstec held at Düsseldorf Fairgrounds, Germany. glasstec is the meeting point for the world of glass, not only the world‘s largest trade fair for the glass industry and its suppliers but also the most international event.STA is a leader in providing clean water solutions without chemicals in the Glass grinding industry. The event was well attended and was also visited by many Indian business houses.